Related products

live a message

It shows good strength, corrosion resistance, high quality surface finishing, excellent weldability, and is easily formed. 5251 aluminum has high fatigue strength, good weldability, and good corrosion resistance. It is seen in the aircraft, marine, automotive, and food processing industries.

Non-corrosive:Even in industrial environments where other metals are frequently corroded, aluminum is extremely resistant to weathering and corrosion. Several acids won't cause it to corrode. Aluminum naturally generates a thin but effective oxide layer that inhibits further oxidation, giving it exceptional corrosion resistance. As a result, objects made from aluminum oxide are nearly impermeable to many corrosive substances.

Easily machined and cast:Since it melts more readily than steel, aluminum coil is more pliable and simpler to pour into molds. Aluminum castings are also less stiff than steel, making them easier to work with while steel castings need a lot more effort. It is one of the most machinable metals available, making processing time cost-effective.

Lightweight yet durable:Aluminum coil is lightweight and portable since it has a low density. This makes it the chosen metal for use in the construction of airplanes. It may be considered as being even more durable since it can be recycled.

Non-magnetic and non-sparking:Aluminum is non-magnetic because of its crystalline structure. An oxide layer is quickly formed after any scratch making it non-sparking.

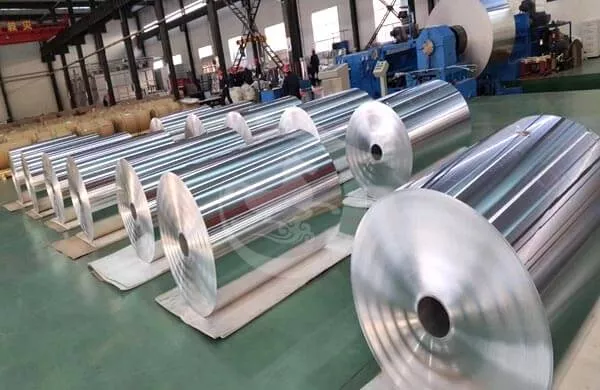

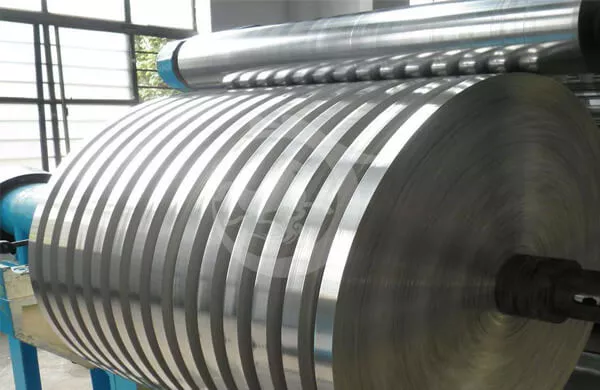

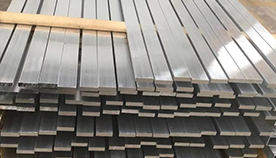

| Product Name | Aluminum Coil |

| Standard | ASTM、JIS、GB、DIN、EN |

| Material | 1060、1100、2A16、2A06、3003、3004、3A21、4A01、5052、5005、5083、5A05、6061、7075、8011 and so on |

| Type | 1000-9000 9 series |

| Width | 15-2000mm |

| Thickness | 0.2-15mm |

| Application | Used in electronics, packaging, construction, machinery, etc. |

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others-Each | Others Total | Al | |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

| Temper | Specified Thickness(in) | Tensile Strength - KSI | Elongationin 2 inches % | |||

| Ultimate | Yield | |||||

| Min | Max | Min | Max | |||

| O | 0.006 - 0.007 | - | 22 | 12 | 12 | 10 |

| O | 0.008 - 0.009 | - | 22 | 12 | 12 | 12 |

| O | 0.010 - 0.020 | - | 22 | 12 | 12 | 14 |

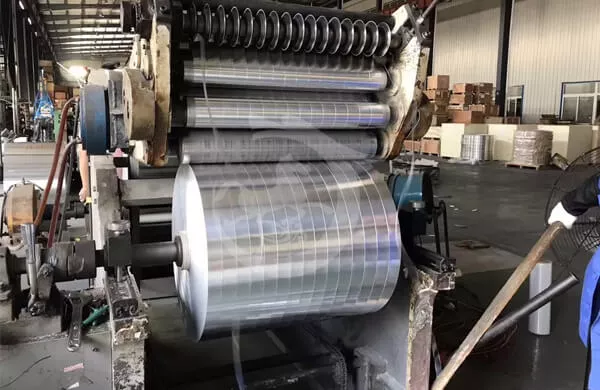

| aluminum coils manufacturers | aluminum coils |

| prefinished aluminum coils | aluminum trim coils |

| 040 aluminum coils | aluminum coils suppliers |

| 1050 aluminum coils | aluminum coils inc |

| 1060 aluminum coils | aluminum coils for sale |

| 1060 aluminum coils for sale | aluminum binding coils |

We are a well known worldwide exporter of aluminum strip , Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

WeChat

WeChat