Related products

live a message

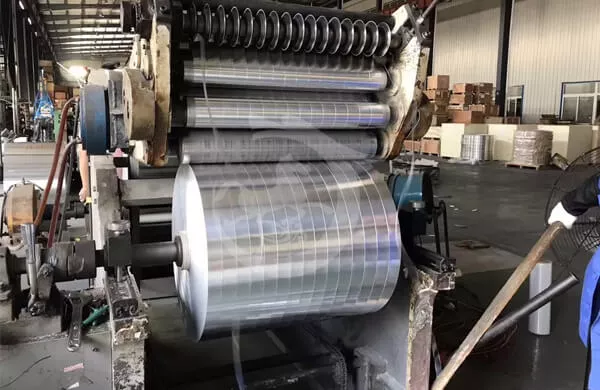

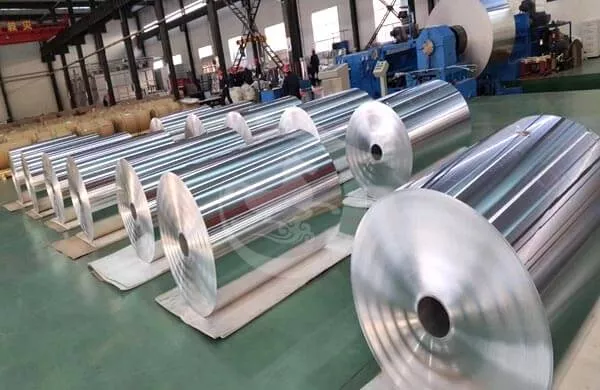

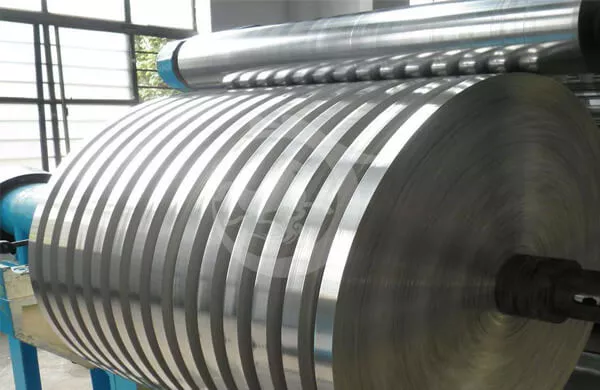

Aluminum strip is made of pure aluminum or aluminum alloy cast and rolled aluminum coils, hot rolled aluminum coils, rolled into thin aluminum coils of different thickness and width by cold rolling machine, and then longitudinally cut into aluminum strips of different widths by slitting machine.

Aluminum strip is made of pure aluminum or aluminum alloy cast and rolled aluminum coils, hot rolled aluminum coils, rolled into thin aluminum coils of different thickness and width by cold rolling machine, and then longitudinally cut into aluminum strips of different widths by slitting machine.

The common alloy grades of aluminum strip are 1050, 1060, 1070, 1100, 3003, 3004, 5005, 5052, 8011, etc. The common states are O state and H state. The common states are O and H. O means soft state, H means hard state, and O and H can be followed by numbers to indicate the degree of softness and hardness, and the degree of annealing.

The specific uses of aluminum strip are: aluminum strip for transformer (transformer aluminum foil), aluminum strip for high frequency welding hollow aluminum strip, aluminum strip for fin radiator, aluminum strip for cable, aluminum strip for stamping, aluminum strip for aluminum edge strip, etc.

The categories of aluminum alloy strips are: pure aluminum strips, transformer aluminum strips, super hard aluminum strips, full soft aluminum strips, semi-hard aluminum strips, and rust-proof aluminum strips.

Aluminum strip is a deep-processed aluminum product formed by slitting and processing aluminum coils. It is an important raw material in the industry.

Depending on the alloying elements contained in the strip, aluminum strip is divided into 8 series, just like aluminum sheet. However, the commonly used series are 1000, 3000, 5000 and 8000 series.

According to the annealing state of aluminum strip, it can be divided into full soft (o-state) semi-hard (H24) and full hard (h18). The most commonly used should belong to the full soft series, because the O state is easier to stretch and bend.

The main processing equipment for aluminum strip is the slitting machine, which can be divided into the required length and width according to the needs. Of course, the equipment for slitting processing is universal and can also be used for processing copper coils, and the processed product is called copper strip.

The international raw material for electronic products is no longer purely dependent on copper tape, because the electrical conductivity of aluminum is just lower than copper, so aluminum tape instead of copper tape is becoming a popular trend in the international.

| Element | 3105 |

| Silicon | 0.6 |

| Iron | 0.7 |

| Copper | 0.3 |

| Manganese | 0.30-0.8 |

| Magnesium | 0.20-0.8 |

| Chromium | 0.2 |

| Zinc | 0.4 |

| Titanium | 0.1 |

| Aluminum | balance |

| Other Elements (each) | 0.05 |

| Other Elements (total) | 0.15 |

| Thickness (inch) | Yield Strength Min. (ksi) | Tensile Strength (ksi) | Elongation (%) | |

| Min. | ||||

| Min. | Max. | |||

| 0.017 – 0.019 | 15 | 19 | 26 | 1 |

| 0.020 – 0.031 | 15 | 19 | 26 | 1 |

| 0.032 – 0.050 | 15 | 19 | 26 | 2 |

| 0.051 – 0.080 | 15 | 19 | 26 | 3 |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Iron & Steel is the hard work and dedication in the steel industry for many years to meet the needs of customers in a timely manner. Advanced technology, standard products, certified quality standards and the best customer service have led me to years of hard work and dedication in the steel industry and to meet customer needs on time. Advanced technology, standard products, certified quality standards and the best customer service make Kuaima Steel a real leader in the global market

quality & experience

Technology & Innovation

Team & Quality

Service & Support

| Material: aluminum alloy A3003, A3005, A3105 | Aluminum thickness: 0.12-1.5mm |

| Strip width: 120,123,125,137,140,173,174,187,229 mm or by customer's option | Interior diameter: 505mm, etc |

| weight: 0.5-3.0T/coil or by buyer's option | Surface treatment: PUPA/PEPA coating |

| Color: white, silver, brown, beige, green, blue and other solid RAL colors, wooden grain,, plain color, metallic, patterned, etc | Dried and baked: oven baked at 450 degree F |

| Coating thickness: 24-26 micron | Coating hardness: (pencil hardness) HB |

| Coating adhesive: no lower than first grade | Impact resistance: no cracking and peeling(50kg/cm, ASTMD-2794:1993) |

| Flexibility(T-bend): 7T or by your option | MEK resistance: more than 100 |

| Outer packing: wooden plate, covering with craft paper and film, Eye to Sky or wall to Sky packing. | |

We are a well known worldwide exporter of aluminum strip , Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

WeChat

WeChat