Related products

live a message

Monel alloy, also known as nickel alloy, is an alloy made of metal nickel as the base and adding copper, iron, manganese and other elements. Monel alloy has good corrosion resistance and is silvery white, suitable for edge wire material.Monel is a solid-solution binary alloy. As nickel and copper are mutually soluble in all proportions, it is a single-phase alloy.

Compared to steel, Monel is very difficult to machine as it work-hardens very quickly. It needs to be turned and worked at slow speeds and low feed rates. It is resistant to corrosion and acids, and some alloys can withstand a fire in pure oxygen. It is commonly used in applications with highly corrosive conditions. Small additions of aluminium and titanium form an alloy (K-500) with the same corrosion resistance but with much greater strength due to gamma prime formation on aging. Monel is typically much more expensive than stainless steel.

Monel alloys have a great deal to offer. Prior to the 1950s, they were the "go to" choice for many critically important industries. It could also be easily welded, soldered, and brazed.

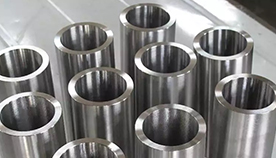

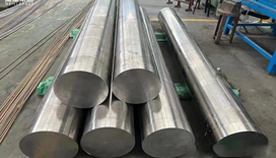

This is because of its:high corrosion resistance to acids and alkalis,high mechanical strength,good ductility (easy to shape and form),resistance to alkalis,relatively low cost,availability in different forms including, hot and cold-rolled sheets, plates, rods, bars, and tubes,attractive appearance and finishes, including a gray-green patina similar to copper

| Element | Content (%) |

| Nickel, Ni | Remainder |

| Copper, Cu | 28-34 |

| Iron, Fe | 2.5 max |

| Manganese, Mn | 2 max |

| Silicon, Si | 0.5 max |

| Carbon, C | 0.3 max |

| Sulphur, S | 0.024 |

| Properties | Metric | Imperial |

| Tensile strength(annealed) | 517-620 MPa | 75-90 ksi |

| Yield strength | 172-345 MPa | 25-50 ksi |

| Modulus of elasticity | 179 GPa | 26000 ksi |

| Poisson’s ratio | 0.32 | 0.32 |

Properties | Metric | Imperial |

Density | 8.8 gm/cm3 | 0.318 lb/in3 |

Product Name | Monel Supplier |

Material | Monel Supplier/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

Specification | Wire: 0.01-10mm |

Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

Product | 1.According to the preparation process can be divided into deformation superalloys, 2.According to the strengthening mode, there are solid solution strengthening type, precipitation |

Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

| alloy steel plate material specification | alloy steel plate factories |

| alloy steel plate price | alloy steel plate factory |

| alloy steel plate pricelist | alloy steel plate in stock |

| alloy steel plate prices | alloy steel plate manufacturer |

| alloy steel plate quotes | alloy steel plate manufacturers |

| alloy steel plate specification | alloy steel plate material |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

We are a well known worldwide exporter of Monel alloy Qatar, Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

WeChat

WeChat