Related products

live a message

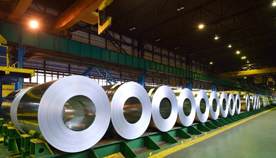

Hot dip Galvanized steel coils are widely used in the construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc. Recommended for both outside and inside usage, galvanized steel has a high resistance to corrosion in different environments, due to a protective layer of zinc of 100 – 275 grams per squaremeter.

Galvanized coil: a thin steel sheet that immerses the steel sheet into the molten zinc bath to make its surface adhere with a layer of zinc. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in the zinc melting bath to make galvanized steel plate; Alloyed galvanized steel sheet. This kind of steel plate is also made by hot dip method, but it is heated to about 500 ℃ immediately after coming out of the groove to form an alloy coating of zinc and iron. The galvanized coil has good coating adhesion and weldability.

GALVANIZED STEEL COIL | |

Standard | ISO,JIS,AS EN,ASTM |

Grade | Q195 Q235 Q345 |

SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 | |

SGHC SGH340 SGH400 SGH440 SGH490 SGH540 | |

DX51D DX52D DX53D DX54D DX55D DX56D DX57D | |

S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD | |

SS230 SS250 SS275 | |

Width | 600mm to 1500mm |

Thickness | 0.125mm to 3.5mm |

Zinc coating | 40g/m2 to 275g/m2 |

Coil weight | 3 tons to 6 tons |

Coil ID | 508mm or 610mm |

Surface treatment | Unoil,Dry,Chromate Passivated, Non-chromate Passivated |

Spangle | Regular Spangle, minimum Spangle,Large Spangle, Zero Spangle |

Capacity | 1,500,000MT/year |

Delivery | 15-25 Days |

| galvanized steel coils | galvanized steel coil prices |

| china color coated galvanized steel coil | galvanized coil steel |

| prepainted galvanized steel coil | galvanized steel coil factory |

| prepainted galvanized steel coil manufacturer | galvanized steel coil sheet quotes |

| china hot dip galvanized steel coil | galvanized steel coil manufacturer |

| galvanized steel coil suppliers | galvanized steel sheet coil quotes |

| galvanized steel coil prices | galvanized steel in coils |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

We are a well known worldwide exporter of Galvanized Steel Coil , Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

WeChat

WeChat