Related products

live a message

Wholesale companies in China are engaged in the aluminum coil market. Get a Quote! Manufacturer of premium aluminum coils. Amazing prices are waiting for you. wholesale price. Advanced technology. quality assurance.

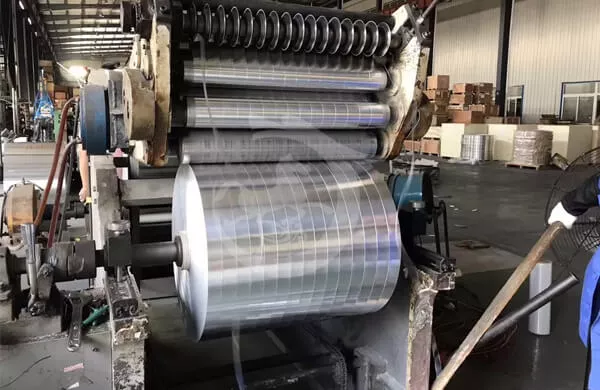

Aluminum coil is cast and rolled machine after calendering, pulling bending angle processing, for the metal products for flying shear.

Aluminum coil is widely used in electronics, packaging, construction, machinery and other aspects, the production process has caught up with developed countries. According to the different metal elements contained in the aluminum coil, aluminum coil can be divided into roughly 9 major categories, that is, can be divided into 9 series, the following step by step roughly introduced.

Technical standards:

Silicon has a corrosive effect on cemented carbide. Although the general will be more than 12% Si aluminum alloy is called high silicon aluminum alloy, the recommended use of diamond tools, but this is not absolute, the silicon content gradually increase the destructive force of the tool also gradually increase. Therefore some manufacturers in the silicon content of more than 8% when the use of diamond tools are recommended.

Silicon content in 8%-12% between the aluminum alloy is a transition interval, can use both ordinary carbide, can also use diamond tools. However, the use of carbide should be used by the PVD (physical plating) method, without aluminum elements and with a small film thickness. Because the PVD method and the small film layer thickness make the tool to maintain a sharp cutting edge become possible (otherwise to avoid the film layer at the edge of the abnormal growth of the need for sufficient passivation of the edge, cutting aluminum alloy will not be sharp enough), and the film layer material containing aluminum may make the blade film layer and the workpiece material affinity and destroy the film layer and the combination of tool substrate. Because the super-hard coating is mostly a compound of aluminum, nitrogen and titanium, it may cause a small amount of spalling of the carbide substrate with the film layer flaking off to cause chipping.

It is recommended to use one of the following three types of tools.

The chip tolerance space of the tool should be large, generally it is recommended to use 2 teeth with large front and back angles (such as 12°-14°, including the back angle of the end teeth).

If only general milling surface, you can use 45 ° main offset angle of the indexable face milling cutter, with special processing aluminum alloy inserts, should be better.

Aluminum oxide was used in the laboratory in 1808 to become aluminum by electrolysis, and was used as a construction material on the spire of the Washington Monument in the United States in 1884 until now; aluminum alloy material synthesized by adding various metal elements has been widely used in various aspects of the construction industry. Aluminum alloy commonly used plate thickness: senior metal roofing (and curtain wall) system is generally 0.8-1.2mm (while the traditional one is generally ≥2.5mm).

| Product | Aluminum Coil |

|---|---|

| Thickness(mm) | aluminum sheet:0.15-6.0 aluminum plate:6.0-25.0 |

| Width(mm) | 20-2000mm |

| Standard | GB, JIS, DIN, ASTM |

| Surface treatment | Brushed, Mirror, Embossed, Sandblasted, etc |

| Temper | O/H111 H112 H116/H321 H12/H22/H32 H14/H24/H34/H16/H26/H36 H18/H28/H38 H114/H194, etc. |

| Type | coil/sheet/strips/plate |

| Package | Standard export package,such as wooden box or as required. |

| 1000 Series | Industrial Pure Aluminum(1050,1060 ,1070, 1100) |

| 2000 Series | Aluminum-copper alloys(2024(2A12), LY12, LY11, 2A11, 2A14(LD10), 2017, 2A17) |

| 3000 Series | Aluminum-manganese alloys(3A21, 3003, 3103, 3004, 3005, 3105) |

| 4000 Series | Al-Si alloys(4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A) |

| 5000 Series | Al-Mg alloys(5052, 5083, 5754, 5005, 5086,5182) |

| 6000 Series | Aluminum Magnesium Silicon Alloys(6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02) |

| 7000 Series | Aluminum, Zinc, Magnesium and Copper Alloys(7075, 7A04, 7A09, 7A52, 7A05) |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Iron & Steel is the hard work and dedication in the steel industry for many years to meet the needs of customers in a timely manner. Advanced technology, standard products, certified quality standards and the best customer service have led me to years of hard work and dedication in the steel industry and to meet customer needs on time. Advanced technology, standard products, certified quality standards and the best customer service make Kuaima Steel a real leader in the global market

quality & experience

Technology & Innovation

Team & Quality

Service & Support

| 1050 aluminum coils | aluminum coils exporter |

| 1060 aluminum coils | aluminum coils exporters |

| 1060 aluminum coils for sale | aluminum coils factories |

| 1060 aluminum coils wholesale | aluminum coils factory |

| 1060 anti-corrosion aluminum coils | aluminum coils manufacturer |

| 1100 aluminum coils for sale | aluminum coils supplier |

We are a well known worldwide exporter of Aluminum coils, Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon

WeChat

WeChat