Related products

live a message

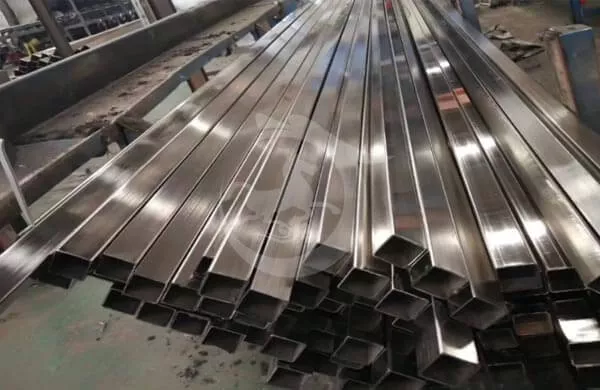

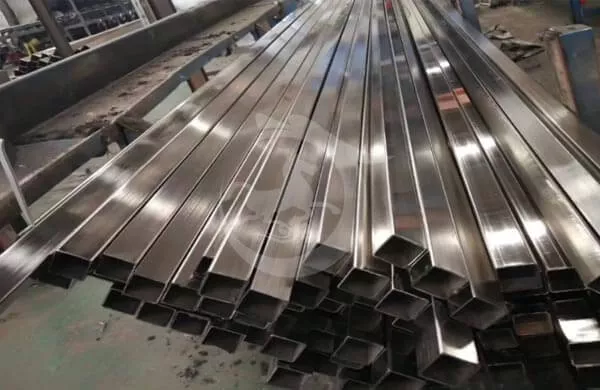

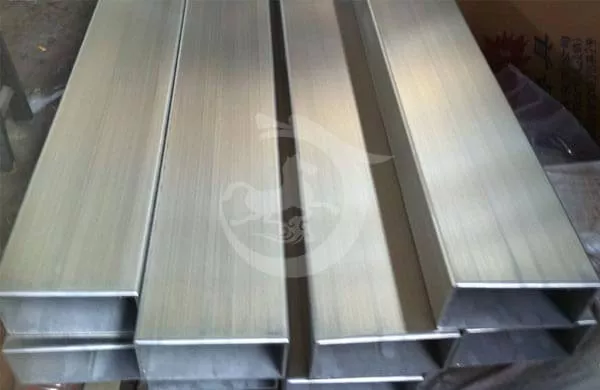

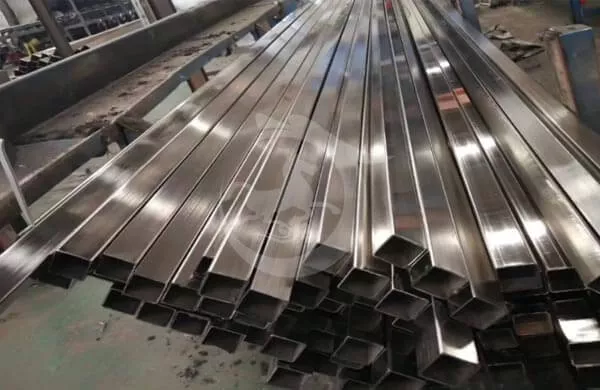

Stainless steel square tube is a kind of hollow long steel, because the section is square, it is called square tube. A large number of pipes are used for conveying fluids, such as oil, natural gas, water, gas, steam, etc. In addition, when the bending and torsional strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures.

201 stainless steel square tube connection methods are diverse: common types of pipe fittings are compression, compression, live joint, propulsion, push threaded, socket welding connection, welding and welding and traditional connection combined with the derivative series of connection methods. These connections, according to its principle, its scope of application is different, but most of them are easy to install, solid and reliable. Most of the sealing ring or gasket materials used for the connection are silicon rubber, nitrile rubber and EPDM rubber, which meet the requirements of national standards and eliminate the worries of users.

Item | 201 Stainless steel square tube |

Product Name | 201 Stainless Steel Square Pipe Manufacturer |

Place of Origin | Shandong,China |

Brand Name | Kuaima |

Material | 201 |

Grade | 200 Series |

Type | Welded,Seamless |

Size | According to customer needs |

Surface | Brushed, Polished, Etched,etc. |

Tolerance | ±1% |

MOQ | Negotiable |

Application | Decoration,Food Grade,Petroleum, Chemical, Medical, Light Industry, Mechanical Instrumentation, etc. |

Standard | ASTM,AISI,GB,DIN,JIS,EN,etc. |

Certification | ISO,CE,etc. |

Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

Payment terms | L/C,T/T,D/P,etc.(According to customer needs) |

Price Term | CIF,CFR,FOB,EXW,etc. |

| Grade | Mn | C | P | Si | Cr | S | Ni | Mo | N | |

| Stainless Steel 201 Pipe | minimum | 5.5 | – | – | – | 16 | – | 3.5 | – | – |

| maximum | 7.5 | 0.15 | 0.06 | 0.75 | 18 | 0.03 | 5.5 | 0.25 | ||

| Grade | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Rockwell Hardness | Elongation at Break (%) |

| SUS201 | ≥275 | ≥520 | HRB≤100 | 55-60 |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success ofuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the best customer service make l is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the best customer service make Kuaima Steel a true leader in zhe global marker

quality & experience

Technology & Innovation

Team & Quality

Service & Support

| 2 1 2 inch stainless steel pipe | 2 inch 304 stainless steel pipe |

| 2 1 2 stainless steel pipe | stainless steel 1 1/2 pipe |

| 2 1 4 stainless steel pipe | stainless steel 6 inch stove pipe |

| 2 304 stainless steel pipe | stainless steel clamps for pipe |

| 2 316 stainless steel pipe | stainless steel exhaust pipe |

| 2 5 stainless steel pipe | stainless steel lily pipes |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

We are a well known worldwide exporter of Stainless steel square tube , Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

WeChat

WeChat