Related products

live a message

The Stainless Steel 310 is a Food grade stainless, hence they are generally used for the manufacturing of various food processing equipment. They are also used in industries such as Pharmaceutical Equipment, Chemical Equipment and Seawater Equipment.

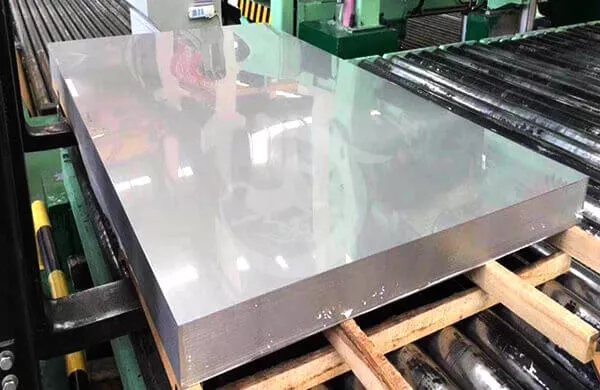

Product Name | Stainless steel plate sheet |

Length | as required |

Width | 10-1000mm or customized size |

Thickness | 0.5-500mm or customized size |

Standard | AISI,ASTM,DIN,JIS,GB,EN,etc |

Technique | Hot rolled/cold rolled |

Surface Treatment | 2B,BA NO.1 NO.2 NO.3 NO.4,4K, 8K,2D, HL, etc. |

Thickness Tolerance | ±0.01mm |

Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L, etc |

Application | Medical devices, building materials, chemistry, food industry, agriculture,ship components. |

MOQ | 1 ton , We can accept sample order. |

Service | ODM/OEM |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success ofuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the best customer service make l is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the best customer service make Kuaima Steel a true leader in zhe global marker

quality & experience

Technology & Innovation

Team & Quality

Service & Support

| stainless steel round plate | 316l stainless steel sheet |

| stainless steel chequered plate | electroplated stainless steel |

| stainless checker plate | 10mm stainless steel plate |

| 304 stainless sheet | 5mm stainless steel sheet |

| 304 ss sheet price | steel kick plate |

| stainless steel threshold plate | 304 ss plate |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

We are a well known worldwide exporter of Stainless Steel Plate 310/310S Qatar, Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

WeChat

WeChat