Related products

live a message

Extensive Product Line Meets Your Industrial Needs. Midway has the ability to fulfill your pipe requirements with a wide range of steel pipe options. We can meet your needs with pipe ranging in diameter from as small as 1 inch and up to as large as 84 inches or even larger.

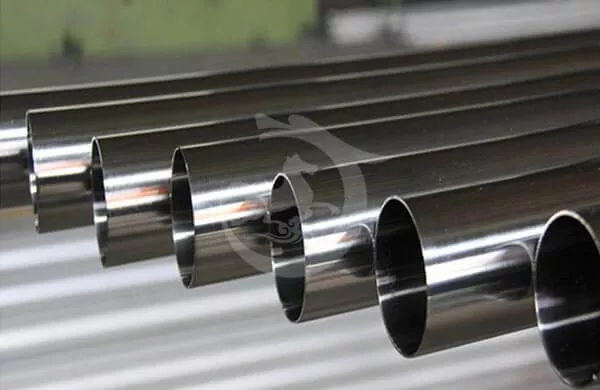

Product Name | Stainless Steel Pipe/Tube | |||

Technology | Hot Rolled Industrial Stainless Steel Tube | |||

Material | 201, 202, 301, 302, 304, 304L, 310S, 316, 316L, 321, 430, 430A, 309S, 2205, 2507, 2520, 430 , 410, 440, 904Lect, Or Customized | |||

Thickness | 0.4-50 mm | |||

Length | 1-12 m | |||

Outer Diameter(OD) | 10-2000mm | |||

Standard | ASTM, JIS, GB, AISI, DIN, BS,EN | |||

Certifications | ISO 9001 BV SGS | |||

Packing | Industry standard packaging or according to client's requirement | |||

Brand | TISCO,ZPSS,Baosteel,POSCO,LISCO,YUSCO,Ansteel, QPSS,JISCO,HXSCO, | |||

Payment terms | 30%T/T in advance, the balance against the B/L copy | |||

Delivery time | Fast delievery in 7 days,up to order quantity | |||

Warehose Stcok | 5000 tons per month | |||

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success ofuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the best customer service make l is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the best customer service make Kuaima Steel a true leader in zhe global marker

quality & experience

Technology & Innovation

Team & Quality

Service & Support

| 3 4 stainless steel pipe | 8 stainless steel stove pipe |

| 304 stainless steel pipe | sch 10 stainless steel pipe |

| 3in stainless steel pipe | stainless steel seamless pipe |

| 4 stainless steel pipe | 1 1 4 stainless steel pipe |

| 1 2 stainless steel pipe | 2 in stainless steel pipe |

| 1 inch stainless steel pipe | 3/4 in stainless steel pipe |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

We are a well known worldwide exporter of stainless steel welded pipe, Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

WeChat

WeChat