Related products

live a message

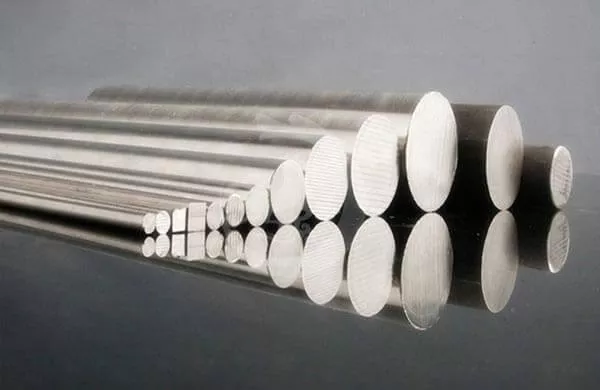

410 stainless steel bar is martensitic (high-strength chromium steel), good wear resistance, corrosion resistance and machining performance is relatively good, generally used as wear-resistant heat-resistant and sharpness required for the use of the occasion, because 410 use most of the time need to quench and temper to improve his hardness and wear resistance, such as cutlery and tableware.

410 stainless steel bar is martensitic (high-strength chromium steel), good wear resistance, corrosion resistance and machining performance is relatively good, generally used as wear-resistant heat-resistant and sharpness required for the use of the occasion, because 410 use most of the time need to quench and temper to improve his hardness and wear resistance, such as cutlery and tableware.

The chemical composition of 410 stainless steel: C ≤ 0.15, Si ≤ 1.00, Mn ≤ 1.00, P ≤ 0.035, S ≤ 0.030, Cr = 11.50 ~ 13.50

Production Process

Process flow of bar production line: billet acceptance → heating → rolling → double-length shearing → cooling → shearing → inspection → packaging → measurement → storage.

Small bars are produced by small rolling mills. The main types of small rolling mills are: continuous, semi-continuous and tandem. At present, most of the new and in-use small rolling mills in the world are fully continuous. Today's popular rebar mills include general-purpose high-speed rolling rebar mills and 4-slice high-production rebar mills. The billet used in the continuous small rolling mill is generally a continuous casting billet, its side length is generally 130~160mm, and there are also 180mm X 180mm, the length is generally about 6~12 meters, and the single billet weight is 1.5~3 tons. Most of the rolling lines are alternately arranged horizontally and vertically to achieve torsion-free rolling across the entire line. The number of stands is determined according to the principle of rolling one stand. Most of the rolling mills are even-numbered pass combinations. For different billet specifications and finished product sizes, there are 18, 20, 22 or even 24 small rolling mills, and 18 are the mainstream. Adjustable speed, micro-tension and tension-free rolling are the obvious features of modern fully continuous small rolling mills. Part of the racks of rough rolling and intermediate rolling are under micro tension control, and part of the racks and finishing mills of intermediate rolling are under tension-free control to ensure the dimensional accuracy of products. Continuous rolling mills are generally equipped with 6 to 10 loopers, and some even have as many as 12 loopers.

Bar rolling is the easiest of all rolled products to achieve, and it can be done in many ways. Bars can be produced from the three-roller row type to the twisted double type, from various semi-continuous types to full-continuous types, but their output, dimensional accuracy, yield, and pass rate are quite different. The rigidity of the three-roll mill is low, and the fluctuation of heating temperature will inevitably lead to serious fluctuations in product size. In addition, the slow speed of the horizontal row and the long rolling time will lead to an increase in the temperature difference between the head and tail of the rolled piece, which is prone to inconsistent dimensions and uneven performance. The yield is very low, the quality fluctuates greatly, and the high quality rate is extremely low. The full-continuous rolling mill generally adopts horizontal and vertical alternation, the rolling piece has no twist, less accidents, and high output, which can realize large-scale specialized production and structure performance control. The qualification rate has been greatly improved, especially the finished product rate has been improved, and the waste of returning to the furnace for steelmaking has been reduced. At present, new technologies such as stepping heating furnace, high-pressure water descaling, low-temperature rolling, and endless rolling are mostly used in bar rolling. Rough rolling and intermediate rolling are developing in the direction of adapting to large billets and improving rolling accuracy. Mainly to improve accuracy and speed.

Compared with ordinary carbon steel hot rolling, the rolling technology and process know-how of stainless steel are mainly reflected in the inspection and cleaning of ingots, heating methods, roll pass design, rolling temperature control and on-line heat treatment of products.

Ingot inspection and cleaning

The cleaning line includes: shot blasting, infrared surface inspection, ultrasonic flaw detection and grinding wheel machine, etc. With the improvement of continuous casting level, if continuous casting can produce defect-free billets, billet cleaning lines may not be added.

| Item | Stainless steel rod |

| Product Name | 410 Stainless Steel Bar Manufacturer |

| Place of Origin | Shandong,China |

| Brand Name | Kuaima |

| Material | 410 |

| Grade | 400 Series |

| Type | Welded,Seamless |

| Size | According to customer needs |

| Surface | Brushed, Polished, Etched,etc. |

| Tolerance | ±1% |

| MOQ | Negotiable |

| Application | Decoration,Food Grade,Petroleum, Chemical, Medical, Light Industry, Mechanical Instrumentation, etc. |

| Standard | ASTM,AISI,GB,DIN,JIS,EN,etc. |

| Certification | ISO,CE,etc. |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Payment terms | L/C,T/T,D/P,etc.(According to customer needs) |

| Price Term | CIF,CFR,FOB,EXW,etc. |

| Chemical Material Composition of SS 410 seamless bar | ||||||||||

| Grade | Ni | Mn | P | C | S | Si | Cr | Mo | N | |

| 410 | min. | – | – | – | – | – | – | 11.5 | – | – |

| max. | 0.60 | 1 | 0.035 | 0.15 | 0.03 | 1 | 13.0 | |||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) | Brinell (HB) | ||||

| 410 | ≥540 | ≥345 | ≥25 | ≤200 | ≥159 |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success ofuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the best customer service make l is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the best customer service make Kuaima Steel a true leader in zhe global marker

quality & experience

Technology & Innovation

Team & Quality

Service & Support

| 316 stainless steel rod | stainless steel rods 1 2 |

| 5 16 stainless steel rod | 1 16 stainless steel rod |

| 5 8 stainless steel rod | 10mm stainless steel rod |

| 1 4 inch stainless steel rod | 12mm stainless steel rod |

| 1/2 in stainless steel rod | 5 32 stainless steel rod |

| 1/4 in stainless steel rod | 316 stainless steel threaded rod |

We are a well known worldwide exporter of Stainless Steel Rod , Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

WeChat

WeChat